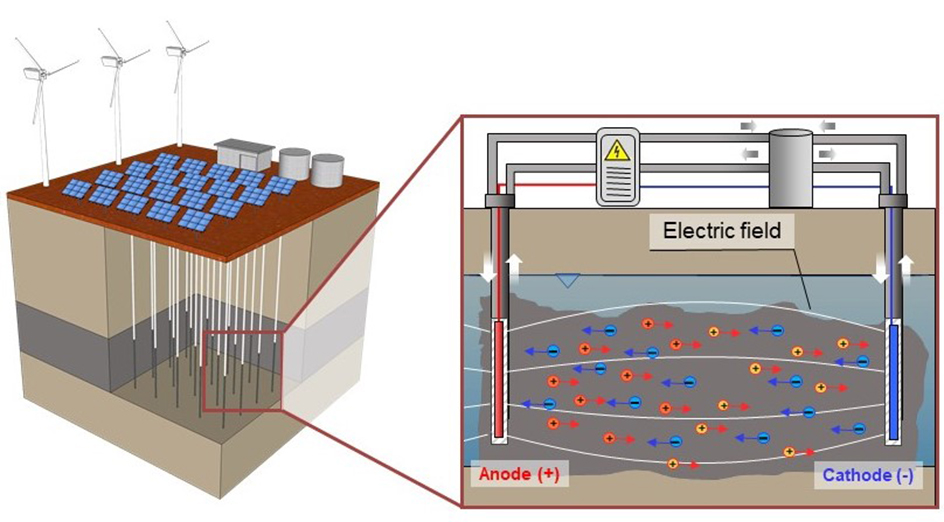

The technique is called electrokinetic in situ leaching (EK-ISL) and it has been previously applied for metal recovery from fly ash, wastewater sludge, soils, and mine tailings materials but not for the recovery of metals from intact hard rock bodies.

EK-ISL combines two existing technologies: in situ leaching, which comprises the application of a lixiviant to selectively dissolve target metals from their ore without excavating its host matrix, and electrokinetics, which comprises the application of a targeted electric field to control and accelerate the transport of the lixiviant or dissolved target metals within the subsurface.

“The metals are extracted within the ore body, instead of the traditional means of having to dig them out and milling huge amounts of material,” Henning Prommer, coauthor of the study and a professor at the University of Western Australia, said in a media statement. “Traditional methods of excavating ore material result in a large amount of solid waste brought to the Earth’s surface which needs to be disposed of, whereas this new method dramatically decreases wastage.”

According to Prommer, global estimates place solid waste from mining at 100 gigatonnes per year, which is significantly larger than any other form of waste generated by humans.

In addition to the environmental consequences of such disposal, Prommer and his colleagues pointed out that the current mining paradigm can be considered unsustainable because, for example, in the past decade there has been a major decline in the discovery of shallow copper ore deposits while the average ore cutoff grade has also decreased by approximately 25%.

The EK-ISL technique was tested in laboratory experiments and through computer modelling

“Many Cu deposits currently deemed ‘Tier 1,’ such as the Pebble East giant copper-gold deposit in Alaska (USA) and the deeper ore zones at the Escondida porphyry Cu deposit in Chile, are buried by hundreds of meters of overburden. Under these circumstances, conventional Cu mining becomes increasingly challenging because of the necessity to remove, process, and store large quantities of waste rock,” the experts wrote in their paper.

In addition to this, their data show that the economic viability of processing such diminishing grade material by relying on the non-stop improvement in the efficiency of mining technologies and the economy of scale means using more energy, water, and land per unit mass of extracted copper.

“Similar considerations also apply for many other commodities,” the researchers adduce. “Consequently, the current mining paradigm can be considered inherently unsustainable, and there is a recognized need for the development of new approaches for more sustainable exploitation of known but currently unviable metal deposits.”

The EK-ISL technique, which proved to be thermodynamically viable to leach Cu at ambient temperature and pressure using relatively environmentally benign lixiviants such as ferric chloride, was tested in laboratory experiments and through computer modelling.

After successfully extracting copper from an intact sulfidic porphyry Cu ore drill core sample, the group is confident the idea will also work in the field, not only for copper but also for a wide range of other metals.

“This is really exciting because we can use intermittent power sources such as solar and wind to extract minerals,” Prommer said.