Ideon Technologies aims to take some of the guesswork out of mineral exploration

So what if you could just X-ray the ground instead?

That’s basically what Vancouver’s Ideon Technologies does, and some of the world’s biggest mining companies are using the technology as a way to take some of the guesswork out of exploration, including Teck Resources (TSX:TECK.B), BHP (NYSE:BHP) and Vale S.A. (BVMF:VALE3), a Brazilian multi-national mining company.

Ideon’s technology detects subatomic particles – muons – that bombard the earth from space. This provides a way of reading what’s underground – a kind of geological X-ray that can paint 3D geological maps for mining and exploration companies.

It can’t tell what types of minerals are underground, but it can describe ore densities. This can take a lot of guesswork out of the exploratory drilling that is needed for mining companies to get an idea of where ore bodies might be and in what concentration. The technology works best with base metals, critical minerals and uranium.

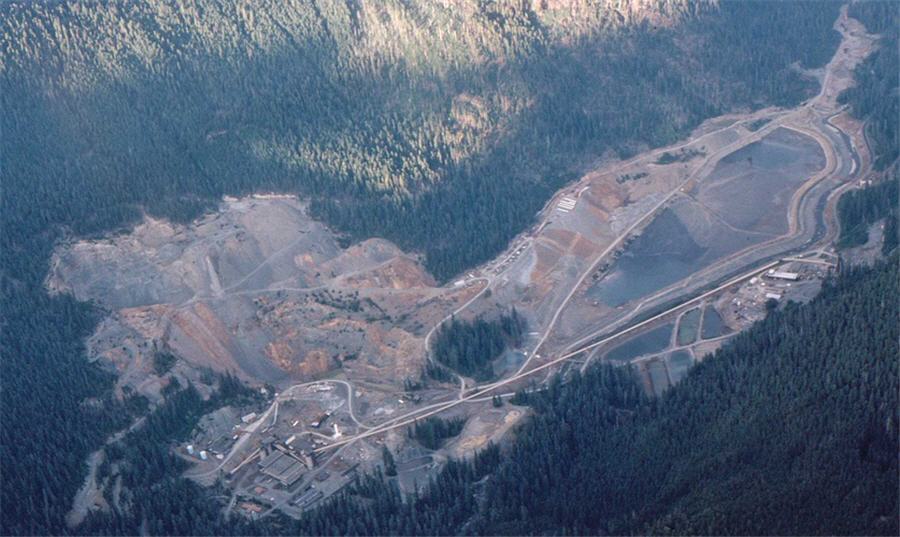

One of the first demonstrations of the technology was in 2012 at the Myra Falls mine on Vancouver Island. Nyrstar Corp. wanted to explore beyond its Myra Falls mine lead-zinc mine, which was acquired in 2020 by Trafigura Mining Group.

But one suspected deposit was underneath a provincial park – Strathcona – and drilling in a Class A park wasn’t much of an option.

So the company asked Ideon to use its new detection system to try to get a reading of what was underneath the park – the idea being that, if it could prove there is an ore body worth exploiting, it could extend its underground mine in that direction without having to go drilling in a provincial park.

Some of the world’s biggest mining companies have since been using Ideon’s detection system. There are about 50 Ideon sensors currently deployed at mineral prospects around the world.

Some companies have tested the technology with blind trials, in which Ideon uses its technology to paint a picture of what’s underground, in terms of ore densities, which is then compared to what the company already knows about it through conventional drilling.

One of these blind trials was with BHP in Australia at a nickel prospect.

“The customer invested in a couple of hundred drill holes in that particular area,” said Ideon CEO Gary Agnew. “So they had already done the work the old way, and then deployed our detectors for two months. We were able to image accurately what they had understood the ore body to be. What was a really important distinction in that particular survey was we were able to image a lobe of the deposit that the customer had missed through drilling.

“We’ve now deployed our fifth survey with BHP. We proved the technology and now we’ve moved onto a number of other surveys on the same site and moved onto an additional site.”

Ideon sensors can be sent down a conventionally sized bore hole. The sensors can only look up, not down, so they must be sunk below any suspected ore body. Sensors take readings of everything that is above it.

Over a period of weeks or months, radiographic images are slowly created and eventually these are worked up into 3D models.

Typically, 10 to 20 sensors are deployed. The deeper down they have to be placed, the longer they have to stay there to get readings, because muons lose energy the further they penetrate the earth.

So the shallower the deposit, the quicker the process is.

It can take anywhere from 30 days to 12 months for radiographic images to form, depending on the depth of the deposit.

“If the customer is time sensitive, we can double the number of detectors on a particular project to halve the imaging time,” Agnew said.

In conventional exploration, it can take many weeks or months to compile all the drill results into a resource report. It takes only hours or days for Ideon to compile its data into a final estimate.

“Some of the other geophysical techniques, the data collection time is very quick, but the post processing is very long,” Agnew said.

“Our data collecting time is a bit longer, but our post processing is very quick.”

Agnew said Ideon’s technology doesn’t eliminate the need for conventional drilling, but can reduce the amount of drill holes needed, which reduces costs as well as environmental impacts.

“If we’re involved in the right stage of the project, we can reduce drilling 10 times,” Agnew said.

Two companies are currently using Ideon technology on uranium prospects in Saskatchewan, and Vale S.A. recently tapped Ideon technology to do surveying at two Canadian projects.

“With the critical mineral shortage, the need to move to renewable energy, we see a tremendous opportunity to help the mining industry find critical minerals more efficiently,” Agnew said.

(This article first appeared in Business in Vancouver)