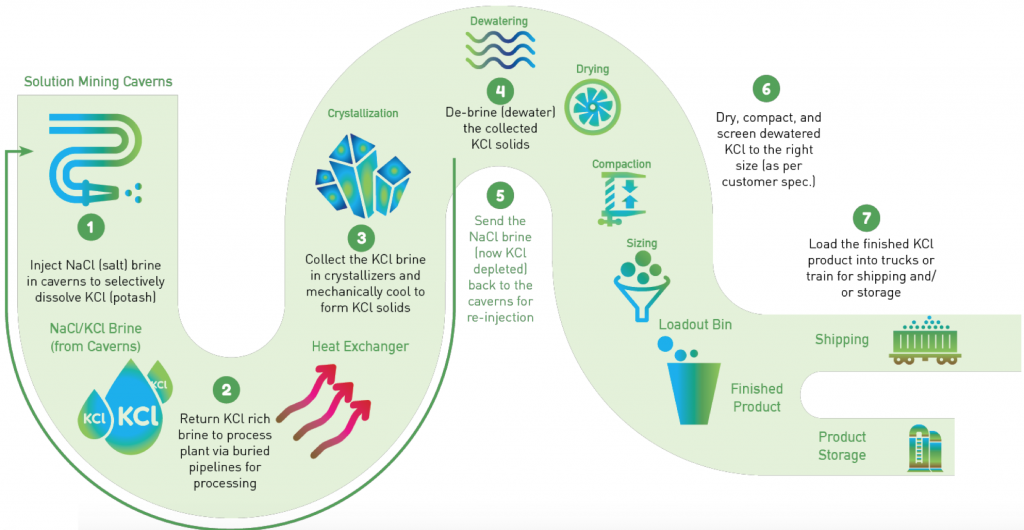

The extraction method that Gensource has created injects a hot salt (NaCl) brine into horizontal caverns in the ore body, which selectively dissolves potash (KCl) leaving salt in place. The KCI-rich brine is then processed (KCI ‘drops out’ through cooling crystallization) and the NaCl brine is reheated and re-circulated back to the cavern to repeat the process.

The process is carried out by a series of independent production facilities that are 1/10th the size of a traditional potash project and can produce between 250,000 – 300,000 t/year of the fertilizer.

Set to be installed at the Tugaske project, which is within the company’s Vanguard Area in south-central Saskatchewan, the modules are said to use 75% less water per tonne of potash than conventional solution mining methods. They also have the ability to use brackish water sources, which reduces freshwater usage even further.

Gensource has also reported that power at Tugaske is self-generated using natural gas, not coal, which avoids up to 24,500 tonnes/year CO2e of emissions.

The Tugaske greenfield project recently received a development approval permit from the Rural Municipality of Huron, where it is located. The Saskatchewan Ministry of Environment, on the other hand, ruled in 2018 that the project should be considered ‘not a development’ because it doesn’t trigger environmental impact assessment due to its ‘green’ attributes.

At present, Gensource Potash is waiting for its senior lenders, KfW and Société Général, to approve financing. The firm is also waiting to have project financing coverage approved through Euler Hermes.

Once operations start, Gensource Potash has committed to selling, for at least the next 10 years, 100% of the annual production from Tugaske to Helm Fertilizers, a US-based subsidiary of Helm AG, who will market it directly to its customers using its own infrastructure.